Rokit Healthcare is a 4D bioprinting and biotechnology company based in Seoul, South Korea. While 4D bioprinting is still a technology in its infancy, it is quickly realizing potential across many fields of scientific research. From materials science to tissue and stem cell regeneration, Rokit Healthcare operates at the frontlines of exploring the many applications of its current set of bioprinting systems, with the ultimate goal of moving its transformative power to the clinical stage. Rokit also always offers their support to their customers such as G-Code Toolpath Service, Grant Support, Seminars and Research Consulting.

At Nexus, while we have built a portfolio of live cell imaging systems, the addition of ROKIT Healthcare’s Dr. INVIVO 4D2 and 4D6 bioprinters to our portfolio, has allowed us to extend our products and services to a new branch of research and clinical applications. We offer both local sales and technical support in the United States.

Please use the buttons below, to book a Journal Club session, to request product information, instrument demonstration and instrument quotation.

What is 4D bioprinting?

As the extrusion-based bioprinter dispenses the cell-laden materials layer by layer, it generates structures that imitate human tissues as well as biological systems that respond to external stimulus. And as these structures are incubated, they grow, change and mature over time which adds the dimension of time as the 4th dimension. This property, makes this bioprinter perfect for the fields of bioengineering and medicine, new drug/product screening, animal alternative experimentation/testing, disease modeling, tissue transplantation and tissue regeneration.

ROKIT Healthcare's Dr. Invivo 4D2 Bioprinter

ROKIT Healthcare’s Dr. Invivo 4D2 is the first clean-chamber bioprinter that is capable of in-situ 4D printing, vessel printing, human tissue model printing, implant printing and many more. With its pioneering technology, 4D2 can print both hard and soft tissues as it can print hydrogels, thermoplastic filaments, freeform cell suspensions, pastes etc. Moreover, as it is a clean chamber bioprinter, it is equipped with HEPA filter, UV lamps for disinfection, bioink warmer, chamber temperature display and HD camera. Furthermore, it come with 2 printheads that can be interchanged between Syringe Dispenser, Fillament Extruder and Hot-melt Pneumatic Dispenser (premium).

Here are some features of the Dr. Invivo 4D2 bioprinter

- Highest temperature range: -4°C ~ 350°C

- Highest pressure range: up to 980 kPa

- LCD touch screen and remote monitoring for controlling the system

- Temperature controlled bed: -4°C ~ 60°C (upgrade or premium systems)

Able to use wide range of materials:

- Synthetic Polymers

- Bioinks (Hydrogel with Cell Mixtures)

- Powder Mixtures (Hydroxyapatite / Chitosan)

- Hydrogels (Collagen / Gelatin / Fibrin / Hyaluronic Acid / Alginate)

- Pellet, Powder & Pastes (PCL, PLGA, PLA, Hydroxyapatite, etc.)

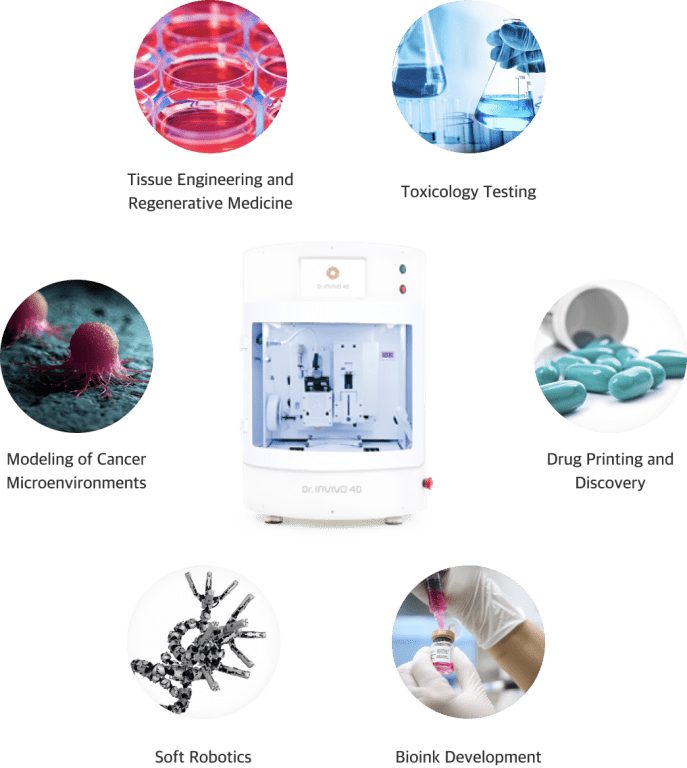

Dr. Invivo 4D2 applications:

- Tissue Engineering and Regenerative Medicine

- Toxicology Testing

- Modeling of Cancer Microenvironments

- Drug Printing and Drug Discovery

- Soft Robotics

- Bioink Development

ROKIT Healthcare's Dr. Invivo 4D6 Bioprinter

ROKIT Healthcare’s Dr. Invivo 4D6 is a more advanced system of the Dr. Invivo 4D2 clean chamber bioprinter. It has the same capabilities of the Dr. Invivo 4D2 and more additional features such as a built-in incubator. With the built-in incubator, the user is able to control the chamber temperature, CO2 levels and humidity of the chamber which supports higher cell viability as well as proper cell proliferation and differentiation in the printed tissue. Moreover, 4D6 has maximum of 6 modular printheads in which it fabricates complex tissue structures with six different cell types and/or materials. Furthermore, the bioprinter is able to work with culture dishes and up to 96 well plate in which the user can create assay composed of organoids or spheroids for drug efficacy and toxicity testing.

Dr. Invivo 4D6 features:

- Built-in cell incubator with controlled chamber temperature, CO2 level and humidity control

- Clean Chamber with Sterilization and Particle control system

- Auto Bed Leveling & Nozzle End Alignment with Ultrasonic Sensor

- Visualization with optical microscope up to 80x resolution

- Multi-Platform Printing Bed (up to 96 well plate and culture dishes)

- Smart User Interface

- High throughput liquid handler

- Modular Printheads with unique pressure and temperature control (1 interchangeable dispenser + 5 rotary bio dispersers)